What tips and techniques about polycarbonate fabrication from this e-book?

Unlock a complete guide to polycarbonate fabrication, bridging the gap between understanding the material and perspex machining techniques. This guide not only delves into the fundamentals of polycarbonate but also provides invaluable insights into enhancing your knowledge of machining processes. Moreover, it offers guidance on designing your product, ensuring a seamless transition from concept to creation.

Chapter One: What Is Polycarbonate?

Chapter Two: Cutting Polycarbonate Sheet

Chapter Three: Bending Polycarbonate Sheet

Chapter Four: Polycarbonate Sheet Printing

Chapter Five: Polycarbonate Milling

Chapter Six: Polycarbonate Thermoforming

Chapter Seven: Polycarbonate Sanding and Polishing

Chapter Eight: Polycarbonate Bonding

Chapter Nine: Polycarbonate Laser Cutting

Chapter Ten: Polycarbonate Finishing Operations

Conclusion

Introduction

Polycarbonate is a popular engineering plastic used in many domestic and industrial applications.

Why?

This is due to its physical and chemical properties. Again, you can easily fabricate it to meet the desired application requirements. With the right equipment, it is possible to process polycarbonate sheets that come in a wide range of sizes and thickness.

Polycarbonate manufacturers employ a wide range of techniques to achieve shapes with detailed finishing and tight tolerance.

In this eBook, you will learn about 9 different polycarbonate fabrication methods used in industries. It will focus on how and when you should choose a particular processing or finishing technique.

However, before we start discussing these fabrication techniques, let’s begin by explain unique facts about polycarbonates.

Chapter One: What Is Polycarbonate?

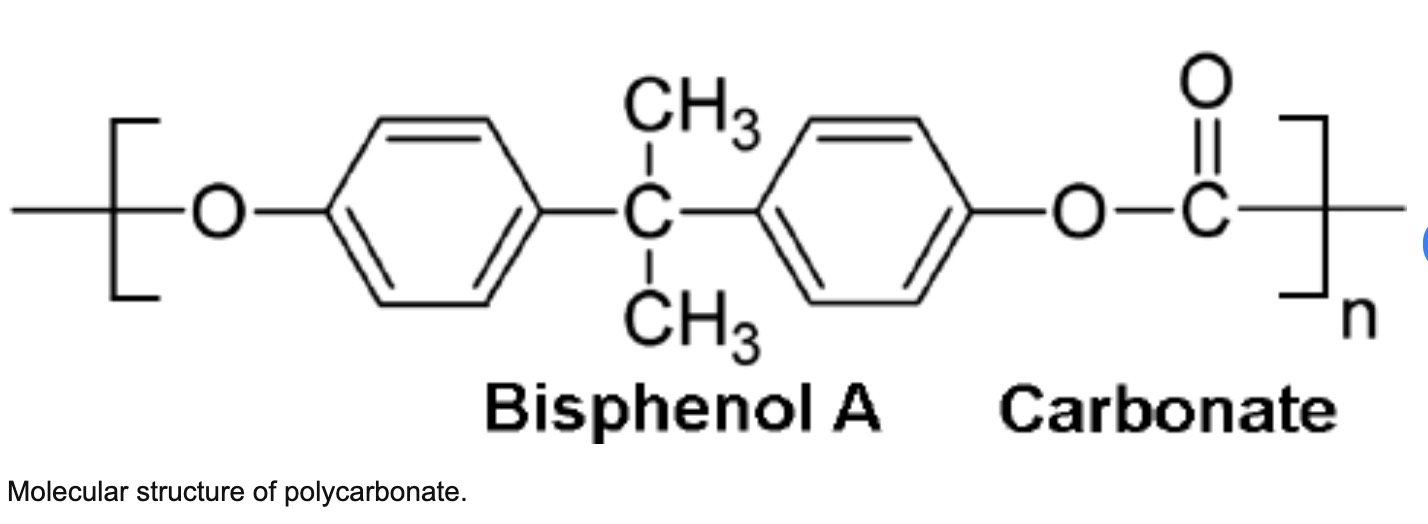

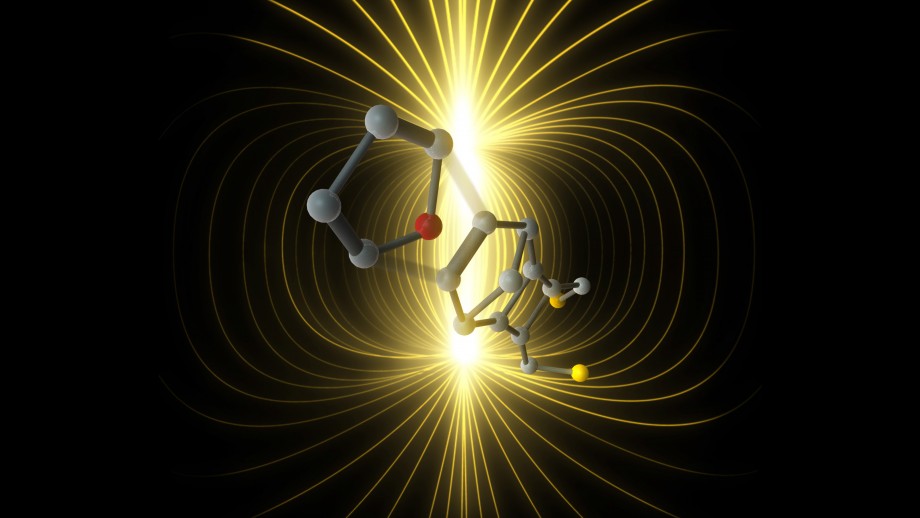

Polycarbonate (PC) is a thermoplastic polymer with the carbonate groups in its chemical structure.

Its structure contains carbon, hydrogen and phenyl groups (aromatic rings). It is these three that are responsible for the desirable chemical and physical properties of polycarbonate products.

Generally, it has a monomer referred to as bisphenol A.

This engineering plastic was disordered in the 1953 by D.W. Fox of General Electric Company, USA and Dr. H. Schnell of Bayer AG, Germany.

By 1958, mass production of polycarbonate had begun and companies such as Dow Chemical, General Electric, Anic and AtoChem joined the industry.

Below, is an image showing the chemical structure of polycarbonate:

polycarbonate chemical structure

It is worth noting the name of this plastic is mainly attributed to its chemical composition. That is, hydrogen, carbon and aromatic rings that form a long molecular chain.

Manufacturing process of polycarbonate sheet is due to a reaction between bisphenol A and carbonyl chloride. On the other hand, bisphenol A is produced by condensation of acetone and phenol. This reaction takes place under acidic conditions.

At the moment, polycarbonate sheet is the most popular engineering plastic used globally. The global demand for the product has increased exponentially over the past decade to more than 1.5 million tons.

This is mainly attributed to superior physical and chemical properties.

Chemical and physical properties of polycarbonates sheet

All these features are attributed to the nature of the bonds that exist between polycarbonate structures. It involves a critical analysis of every single element. This forms a critical part when optimizing the general performance of this material.

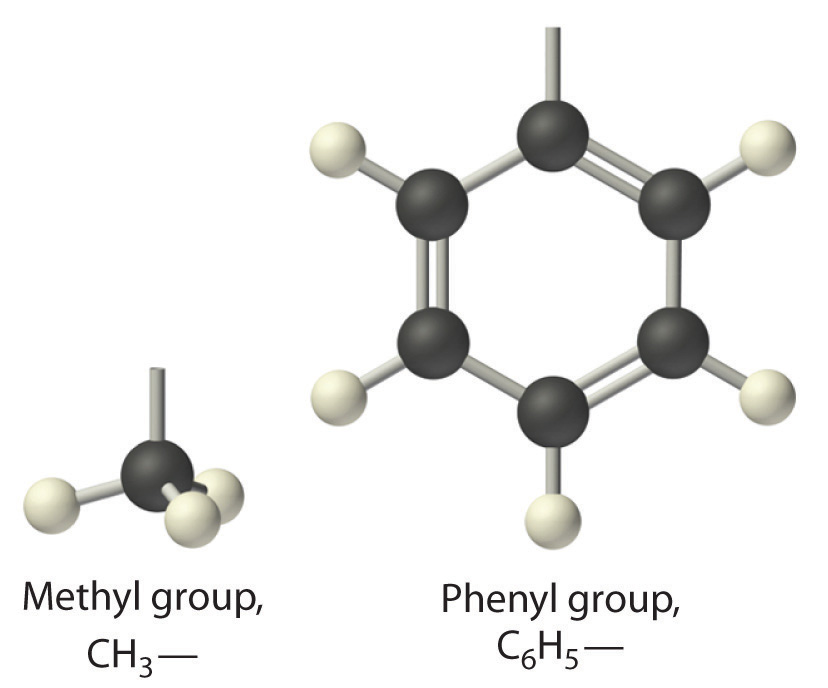

Therefore, most manufacturers focus on analyzing both the phenyl and methyl groups.

phenyl and methyl groups

Physical properties of polycarbonates

1. High strength

It can withstand a large amount of impact. This explains a reason why PC sheets are a perfect choice for hurricane barricades, anti-ballistic shields and glazing applications, just to mention a few.

The sheet is generally shatterproof. Normally, the magnitude of impact it can resist will also depend on the thickness of the sheet.

Ideally, polycarbonate sheets have a compressive yield strength of 70MPa and modulus of 2.0GPa.

2. Optical properties

Polycarbonates are transparent plastics that can transmit up 99.99% of visible light. The aromatic rings prevent the formation of crystalline structure. Crystalline structure tends to undermine optical properties of substances.

On average, polycarbonate sheets have a refractive index of 1.584.

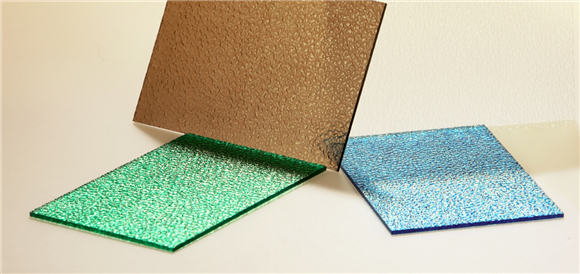

Normally, companies that manufacture polycarbonate sheets may decide to manipulate optical properties to suit a given application. The process may include tinting or embossing.

Tinted and embossed polycarbonate sheet

3. Dimensional stability

Both phenyl and methyl structures make polycarbonate rigid. Again, due to their amorphous structure, polycarbonates experience little elongation when subjected to high stretching or compressive forces.

4. Electrical resistance

There is zero mobility of electrons within a polycarbonate structure. Therefore, it is considered an insulator. Of course, this is attributed to the existence of molecular forces between its molecules.

5. Heat resistance

Polycarbonate will maintain its desirable physical and chemical properties at extreme temperatures. That is, between 140°C to -20°C. This makes them a perfect choice for most electrical applications.

Polycarbonate heat resistance

6. Self-extinguishing

Polycarbonate is self-extinguishing. That is, it is classified as UL94. They do not burn during fire outbreak, thus, a perfect choice in fire prone areas.

Chemical properties

Here, you will understand how polycarbonate may react with other substances or chemicals. These are important factors that play a pivotal role in performance and reliability of polycarbonate sheets.

1. Reaction with chemicals

Polycarbonate is generally resistant to dilute acids, mineral oils, vegetable oils and alcohols. However, it is worth noting that it reacts easily with bases, esters, aliphatic hydrocarbons, oxidizing agents, halogenated hydrocarbons and concentrated acids.

It is for this reason that most polycarbonate manufacturing companies recommend certain cleaning agents.

Reaction with chemicals

2. Water absorption

These plastics absorb a very small amount of water (<0.6%). However, they may begin to decompose when washed for a long time in hot water. The fact that polycarbonates absorb a low amount of moisture makes them dimensionally stable

Water absorption

Again, it is due to this that manufacturers employ different mechanisms to ensure that the final product has the desired performance properties.

For example, during molding, polycarbonates are subjected to a ventilated or dryer temperature of 120° C and 0.1% humidity.

In addition to these, polycarbonates are not inherently resistant to scratched and UV radiation. This is actually the main reason manufacturers add certain chemical additives to improve their performance.

A good manufacturer should avail all test results to verify the physical and chemical properties discussed above. These tests many include: impact analysis, tensile strength, thermal and light transmission tests.

With all these, it is possible to classify polycarbonates based on design and structure. Normally, this is where polycarbonate manufacturers use their ability to fabricate it into desired shapes and parts.

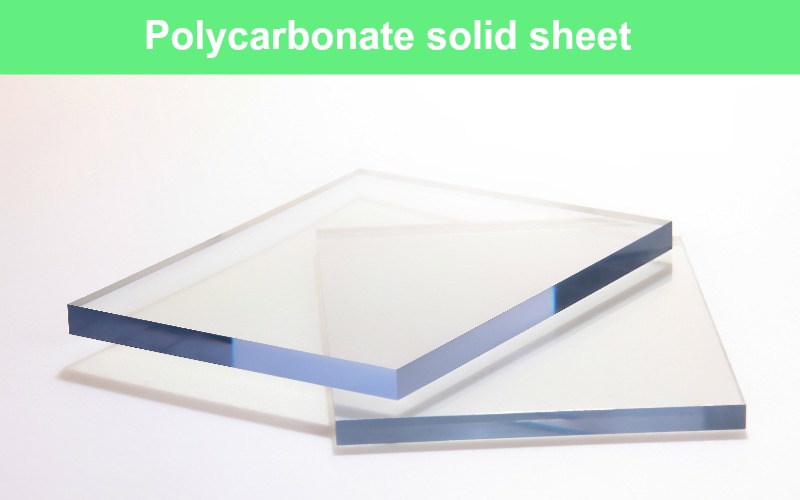

Classification of polycarbonates

They are available in form of panels or sheets. They don’t have air spaces between the polycarbonate sheets and are popular for their high impact strength and excellent optical properties.

Polycaronate solid sheet

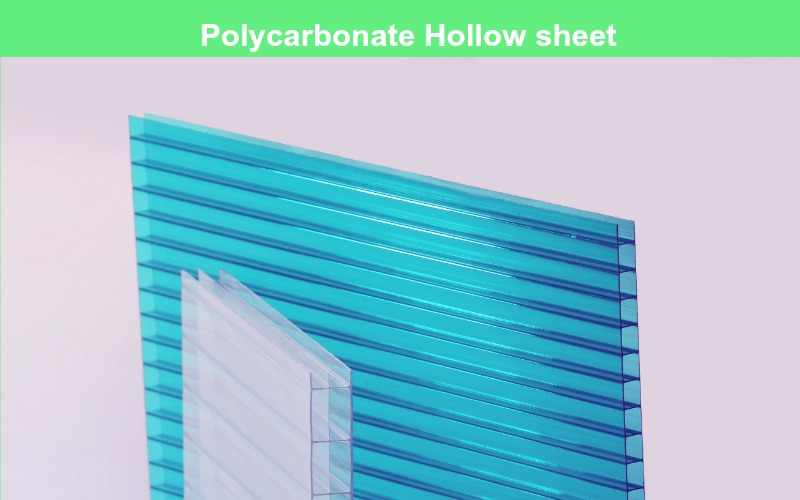

As the name suggests, they have air spaces in between the layers of polycarbonate sheets. They provide an excellent insulation. The dividing walls between the layers act as a supportive structure.

Classification criteria is based on the number of walls – twin, triple, etc.

Polycaronate hollow sheet

These polycarbonate structures can either be hollow or solid. Their shape resembles those of traditional corrugated glazing iron sheets. This shape makes them tough and strong.

Corrugated polycarbonate sheet

As a result, this material is used to make a wide range of materials these include:

Application of polycarbonate sheets/panels

Some of the most common applications of polycarbonate sheets include the following:

Swimming pool enclosure

Glazing application – such as roofs

Protective gears such as ballistic shields

Bullet screen windows

Food containers, just to mention a few.

The numerous applications are due to the benefits that polycarbonates offer as opposed to glass and other plastics.

Benefits of polycarbonate sheets

As you might have noticed, some of these benefits are quite evident in previous sections discussed above. A quick summary of these benefits includes:

- Impact resistant, thus, regarded as virtually unbreakable.

- They come with UV blockage capability

- Extremely light weight

- Excellent optical properties

- Resistant to heat and self-extinguishing

- Durable and reliable

- Easy to customize and fabricate

In short, it is quite evident why most people prefer polycarbonate sheets.

But, how can you customize polycarbonate sheet for a given application?

This is only possible through polycarbonate fabrication. In the next chapters, we shall discuss different techniques of polycarbonate fabrication that are commonly used in the manufacturing industries. These include:

Cutting

Bending

Polycarbonate sheet printing

Polycarbonate Milling

Thermoforming

Sanding and polishing

Polycarbonate finish

Bonding

Laser cutting

Chapter Two: Cutting Polycarbonate Sheet

Cutting polycarbonate sheet is a common fabrication technique. There are two options here:

Let the manufacturing company cut polycarbonate sheets to size or,Opt for DIY process.

Normally, the manufacturing companies have standard machinery and tools to cut polycarbonates. That is, you are guaranteed of precise and quality finishing. Of course, this will be based on a specified tolerance.

As a matter of fact, polycarbonate sheets come in a wide range of sizes and thickness. Therefore, for your custom made project such as polycarbonate swimming pool cover; you will be required to cut them to size.

Polycarbonate swimming pool cover

Cutting polycarbonate to size is not as difficult as many people perceive. However, for the success of this fabrication process, you have to choose the right tool and equipment. One of the most crucial tools is the cutting tool. Let’s discuss some of these tools before we start on the actual cutting process.

Tools used to cut polycarbonate sheets

Cutting tools

This is an important tool whenever you need to cut polycarbonate to size. First, the choice of your cutting tool will depend on the size and thickness of the sheets.

Broadly, you can choose between manual and automated (electric powered) cutting machines. However, the driving mechanism alone is not enough, you need to assess the type of teeth of each saw. The arrangement of these teeth determines whether you will get a precise cut part or not.

There are two types of saws:

1. Circular saws

Circular saws are mainly powered by electricity. Therefore, you need to define speed range, size of the blade and size of polycarbonate sheet you’d wish to cut. Other parameters you need to define are the size of polycarbonate

Circular saws

NOTE: When sawing thin gauge polycarbonate sheets, it is advisable to choose a good supporting edge. Again, there should be a small gap between the supporting table and saw blade.

The table must be free from any projections that may scratch the polycarbonate sheet surface.

When you opt for a circular saw to cut a polycarbonate sheet, there are certain challenges that you will have to deal with. These include:

Gummed or melted edge of the cut part

In such situations, you need to consider the following solutions:

Reduce number of polycarbonate sheet in stack. That is, in case you were cutting more than one sheet at the same time.

- Use a larger blade tooth.

- Increase cutting speed

- Consider using a lubricant but it must be one recommended by the polycarbonate manufacturer.

- Increase feed rate

- Try cooling the cutting blade

- Check blade alignment and inspect it for sharpness.

Any of these should solve the above problem. Another problem is:

Chipping

Well, in case a polycarbonate sheet begins to chip during the cutting process, you may consider any of the following main solutions:

- Reduce blade tooth size

- Inspect blade for sharpness

- Reduce feed rate

- Increase saw size

- Provide better support/clamping

- Check if the blade is firmly fixed

2. Band saws

These cutting tools are mainly characterized with large teeth. They are mainly used to cut polycarbonate sheet with thicker gauge.

Polycarbonate CNC cutting machine

Cutting such sheet may be a challenge at times for additional finishing operations may be required. Polycarbonate finishing operations will be discussed in the coming chapters of this eBook.

Like in the case of the circular cutting tool, the main problems you are likely to encounter include:

Chipping of polycarbonate sheet

You need to consider the following procedures:

- Check blade sharpness

- Provide an additional clamping mechanism

- Reduce tooth size

- Reduce feedstock rate

Gummed or melting edges

Consider the following key procedures:

- Increase tooth size

- Check cutting blade for sharpness

- Cool cutting blade – blow air over it.

- Reduce saw speed

Measuring equipment

You will use this to determine the exact parts to cut. This could be a tape measure.

Safety gears

These include safety goggles, and gloves.

Other equipment includes: pencil (marking), additional breather/filter taps and clamping mechanism.

Polycarbonate cutting process

You can achieve this process by following these simple procedures:

1. Wear protective gloves, goggles and any safety gear you feel is necessary for polycarbonate fabrication.

2. Take accurate measurements of the exact size you want to cut using a tape measure. Mark the section using a pencil.

3. Clean your workbench to ensure there’s no substance that may scratch its surface. NOTE: Neither kneel, nor lean on the polycarbonate sheet.

4. Carefully clamp polycarbonate sheet. It is advisable that you use a soft cloth between the clamping edges. This is to avoid stress can arise by tightening the clamp.

5. Be in the right position with your cutting tool. Don’t force the cutting tool into the sheet. Allow the cutting tool to do its work since this produces better finish.

6. Lift the cut section, then tap it gently with your palm. This helps to remove excess debris.

7. Peel back the protective film (approximately 25mm) and apply a breather/filter tape to the polycarbonate sheet.

Polycarbonate cutting process

The process may look simple, however, failure to follow the recommended cutting procedure can lead to wastages. Again, if by any chance you are not confident enough, it is advisable to hire a trained technician.

In short, as you might have realized, cutting polycarbonate is one of the simplest and most common fabrication technique.

Chapter Three: Bending Polycarbonate Sheet

At times, polycarbonate sheets may be bent to conform to certain shapes. This will mainly depend on the nature of the application. Thus, companies will use different polycarbonate bending techniques.

The fact that polycarbonate has outstanding toughness implies, it can be bent. That is, it can either be:

1. Cold line bent or,

2. Hot line bent

These are two different processes that take place in different fabrication environments. That is, one is carried out at slightly higher temperature that the other. This will be expounded on later in this chapter.

Polycarbonate bending process

Polycarbonate bending machine

For accuracy and consistency of these bends, it is advisable to go for a computer controlled machine. This is because they will bend polycarbonate sheet to any angle accurately.

As a matter of fact, computer controlled machines have become popular in the recent. Every company that fabricates polycarbonates claims to be having the best machine.

The best thing about computer controlled machines is that, a wide range of polycarbonate bending operations can be carried out easily. In the recent past, bending has become a common fabrication technique across many industries.

Polycarbonate bending machine

Basic facts about polycarbonate bending

When bending polycarbonate sheet, the surface is subjected to two forces – compressive and stretching force. These forces should be controlled carefully to avoid any cracks or fracture.

The amount of force required will depend on the stiffness of the polycarbonate sheet. Therefore, before the bending process begins, it is advisable to refer to the product datasheet to be sure of all these parameters.

This follows that, there are a number of precautions that you must have in mind during the process. These include:

1. High stress

When you subject a polycarbonate sheet to a high stress during bending, then chances of chemical stress cracking will be high. So, what should you consider to be high stress?

Well, this may vary depending on the thickness of a polycarbonate sheet. However, any pressure that is above 1500 psi is likely to cause high stress.

Again, polycarbonate is not inert. That is, it is affected by certain chemicals. Therefore, in aggressive environmental conditions, it should be subjected to less stress. You can also opt for polycarbonate sheets with chemical resistant coating.

2. Unprotected polycarbonate sheets

Normally, when bending polycarbonate sheet that is not protected, it must not be cold bent to a radius that is tighter than 100 times its thickness. Remember, the most crucial fact here is to reduce stress that can cause fracture or cracking.

Classification of polycarbonate bending techniques

Broadly, this process is classified based on the temperature required during the bending process. That is, it can either be a cold or hot bending process. Of course, there are certain conditions that such a product must fulfill by all standards.

Take for example the hot bending process. Here, you will heat its surface evenly as you pre-dry the polycarbonate sheet to avoid formation of bubbles. Normally, such heaters require an electric current.

The bottom line is, the nature of the process involved will depend on customer requirements. The most important thing is the ability for companies to adopt a specific method that will guarantee zero errors.

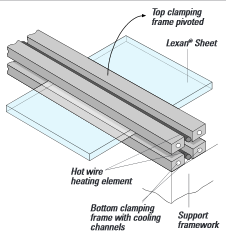

Hot line bending

During hot line bending, a significant amount of heat is required to facilitate the process. It is commonly used to bend thick sheets more so, when an acute angle is desired.

In this fabrication technique, the machine used has an electric heater. That is, during the bending process, polycarbonate sheet is heated along the line of the bend. Depending on the polycarbonate grade, the sheet can be heated on both sides.

Hot line bending

The only disadvantage that comes with heating one side of the polycarbonate sheet is that, you may be required to turn polycarbonate sheet severally. This is to ensure that the heat is distributed evenly on the surface of the polycarbonate sheet.

In most cases, the heating process can be done when polycarbonate sheet has its protective masking.

Though the heating temperature may vary, a number of polycarbonate sheets may be formed when the temperature is between 155°C and 165°C.

The computer controlled polycarbonate bending machines are fitted with temperature controlled heaters. This eliminates the manual process of switching on and off

polycarbonate bending product

of heater manually. Computer controlled machines are mainly suitable for large scale production purposes.

With a hot line bending, all polycarbonate sheets of all sizes can easily be bent to a desired shape. But again, reviewing the polycarbonate data sheet is crucial to choose the best bending machine and configure the right settings.

Cold curving

This process does not require the use of heat. Normally, the bending radius will depend on the thickness of the polycarbonate sheet.

A polycarbonate sheet is clamped and a slight bending force is applied across the sheet. This bending force should not exceed the recommended values because it may alter the performance characteristics of the formed part.

As a matter of fact, subjecting polycarbonate sheet to excess force will make it susceptible to certain chemicals.

As a general rule, bending radius should be a minimum of 100 times the thickness of the sheet. Take for example, the recommended bending radius for a sheet which is 2.0 mm thick will be 350mm.

Cold line bending

This is also a common procedure in the industry. Still, the thickness, magnitude of force, and bending machines determine the accuracy of the part. The overall requirements are similar to that of cold curving.

Cold line bending draft

Precautions when bending polycarbonate sheets

Bending polycarbonate is a delicate process. Therefore, it is important to take the following key precautions:

- Don’t use sharp bending tools, they may damage the sheet.

- Never force the sheet to conform to a specific shape/position.

- You can over bend the polycarbonate sheet to compensate for the stress relaxation that may occur.

- For textured polycarbonate sheet, the textured surface should be in the compression – inner section.

- Cold bending should be done within a short period of time.

In summary, when you follow all these instructions, there is a higher probability that the fabricated part will meet the desired performance criteria.

Apart from bending polycarbonate sheet, another fabrication technique is:

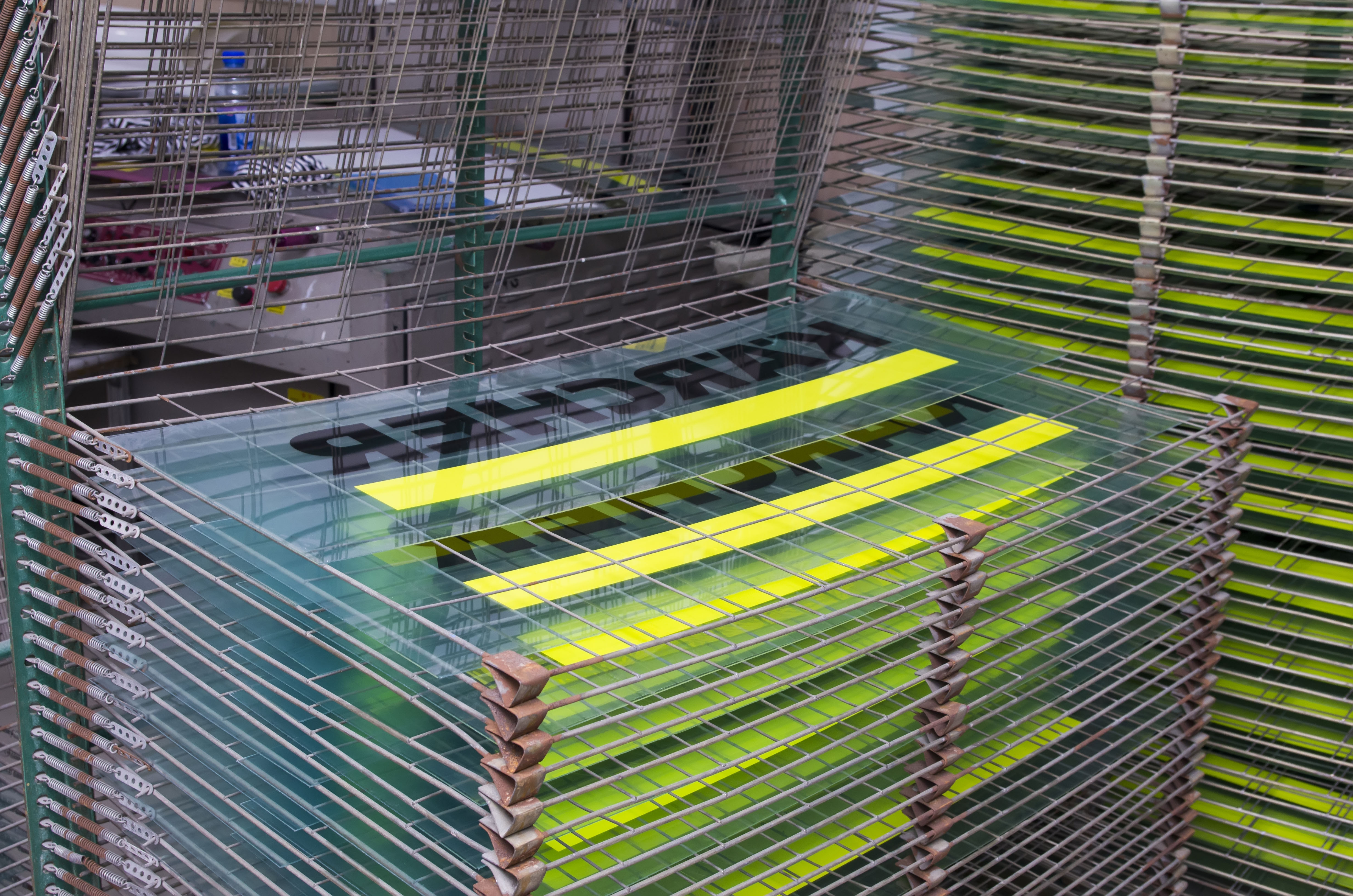

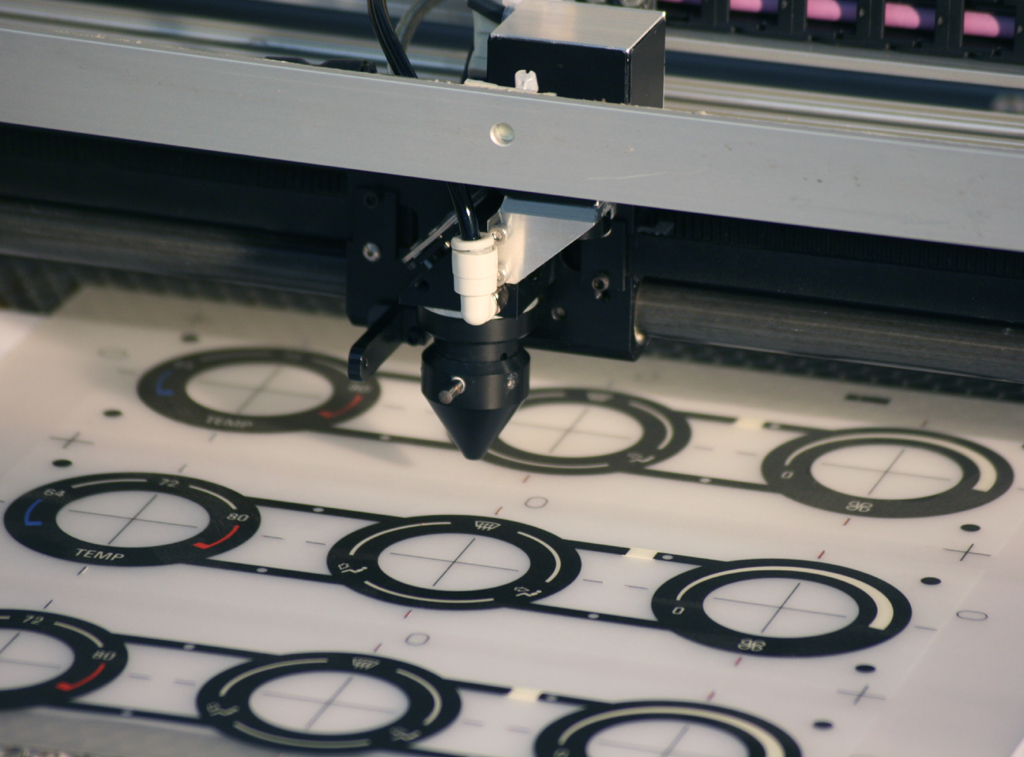

Chapter Four: Polycarbonate Sheet Printing

Printing is an essential procedure when processing polycarbonate sheets. Ideally, the process aims to add value to this plastic sheet. That is, you may decide to incorporate specific graphics or instructions on the polycarbonate sheet.

Furthermore, it has become an important process when it comes to branding. Companies can print their logos or an information they use to reach out to their targeted audience.

Be it a touch pad panel for instrument screens, swings, baseball backboards, freezer doors or skateboards, they can be printed with the modern printers.

Basketball backboard

Availability of different types of polycarbonate materials makes it possible to realize a wide range of graphic and architectural design requirements. As a matter of fact, polycarbonate sheets are a perfect choice for this task due to the fact that they are stronger and visually unbreakable.

Polycarbonate printing machines

The choice of machine forms an integral part of this process. Apparently, there are high definition and full-color printing machines. They can print large sheets – up to 5 by 10 inches.

Polycarbonate printing machines

Polycarbonate manufacturers and printing companies have invested in a wide range of printers such as digital and silk screen printers. The main advantages of silk printing are:

- Cost effectiveness

- Quality prints

- Automated hence, they are faster

- Efficiency

These are some of the main reasons why it is popular in polycarbonate printing industry. On average, these companies can print about 5,000 polycarbonate sheets every day.

Advantages of polycarbonate printing

This polycarbonate fabrication technique is popular due to the following key reasons:

- Can produce both backlit and front-lit graphic panels.

- Effective way of decorating polycarbonates both for interior and architectural design.

- A versatile process used in many applications where all types of polycarbonate sheets can be printed. Be it pebbled textures, varying thickness or different tints.

- Cost effective and reliable.

- Polycarbonate has excellent ink adhesive characteristics

- No pretreatment required, thus, cuts no extra cost.

Screen printed polycarbonate skateboard

From above, it follows that, the printed polycarbonate sheet can retain its desirable properties even when it required additional processing. These polycarbonate sheets can further be thermoformed, bent or hard coated. It simply enhances its performance.

Factors to consider in polycarbonate screen printing

Unlike the traditional way of decorating plastic surfaces (painting), screen printing is highly recommended for large scale tasks. This is mainly due to its cost effectiveness. However, for the printing process to be successful, there are a number of things technicians must consider. These include:

1. Choosing the right printing machine

This will be based on the maximum number of sheets you would wish to print. This could be 5,000 sheets per day or less than. In such situations, you need to go for an automatic and a powerful screen printer.

2. Printing ink system

As much as polycarbonate sheets have good adhesion to most inks, still, you need to choose one that is effective and reliable. The best way to go about it is to ask your screen printer supply distributor or refer to the technical manual.

When considering a printing ink system, it is important that you pay attention to the following key elements:

- Type of mesh

- Squeegee

- Stencil

- Thinners

These are some of the most important variables that determine the amount of ink deposited on the polycarbonate sheet. Of course, the amount of ink will determine the final graphics on the sheets.

Polycarbonate printing ink

3. Material selection

Generally, polycarbonates have high dyne level. That is, they have better in adhesion than other plastics. However, the polycarbonates are available in different grades. Choose one that meets specific requirements of your applications.

In addition to these, polycarbonates can also withstand higher curing temperature than most plastics. Thus, there is no surface pretreatment before printing. Again, printers can maintain better registration.

Common polycarbonate printing failures

At times, this process may not be as smooth as one may think. That is, technicians have to handle certain issues such as:

1. Incompatibility issues

Use only those printing inks and transfer tapes recommended by the manufacturer. This is a common problem, especially if you fail to read manufacturer’s instructions and recommendations.

2. Residual solvents

This may cause poor ink adhesion, polycarbonate sheet curls and stress cracking. These are mainly due to poor drying procedure. Most inks used in polycarbonate printing dry within a temperature between 130°F and 150°F. You need to observe this at all times.

Silk screen printing

NOTE: As a general rule, you must not take manufacturer’s instructions at face value. You need to understand all the details to ensure that the process is actually successful.

You should be able to conduct an in-house test such as cross hatch test. This test is mainly used to check the compatibility of the ink and effectiveness of the overall bonding. This could be between various ink coats and polycarbonate sheet.

At any given time, you should strive to get printing technique that can guarantee success. If possible, document all steps and procedures so that it may act as your reference. It is all these variables that will determine the success of the entire process.

The process of choosing a polycarbonate printing ink is crucial. This is in the sense that, some inks may contain certain chemicals that reduce the shelf life of polycarbonate films. It is for this reason that you need to scrutinize all the basic constituents of the printing ink.

Remember, earlier, in this eBook, I had highlighted all the basic chemicals that affect the performance of polycarbonate sheet. A good example is concentrated acids.

Concentrated acids

In short, screen printing is an important fabrication process that has been adopted by most manufacturing companies. It makes printing more efficient and beautiful. It doesn’t matter whether you intend to use it as a final product or you need to process polycarbonate further.

The final product will definitely meet the performance criteria.

This is not all, the next polycarbonate fabrication method is milling. It is an important fabrication technique as you will discover in chapter 5. Of course, it involves removal of certain sections of polycarbonate sheet with the help of a milling machine.

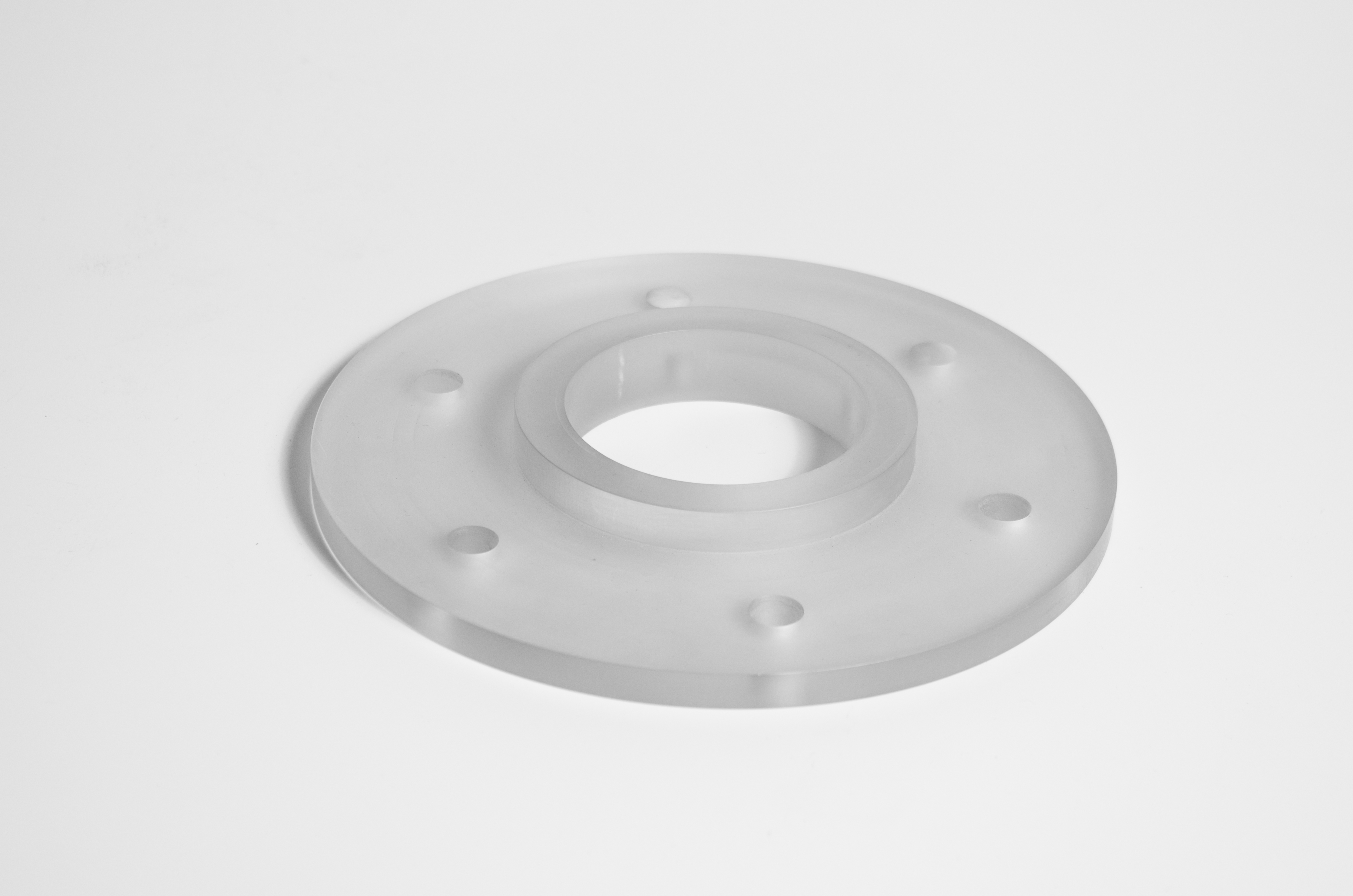

Chapter Five: Polycarbonate Milling

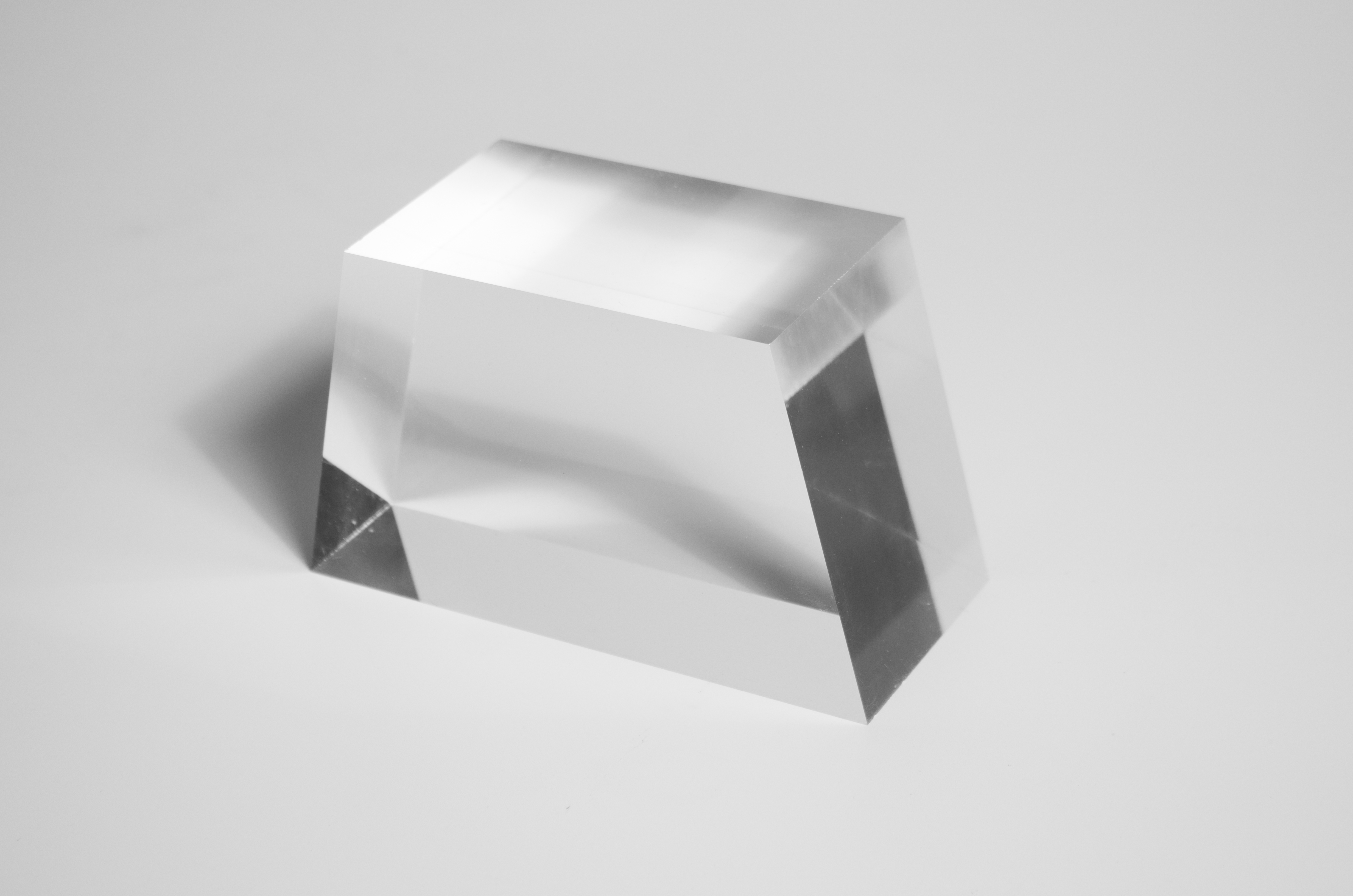

Milling is a popular fabrication technique used to add precision features on polycarbonate parts. Generally, the process involves using milling cutters to remove unwanted sections. These cutters are designed to move perpendicular to the axis of the work piece.

One of Polycarbonate milling product

This polycarbonate fabrication technique is ideal in situations where tooling cost is likely to be high, especially for small scale production.

Milling is commonly used alongside other manufacturing processes such as CNC routing and vapor polishing. The two will be discussed later in this chapter.

Unlike polycarbonate cutting, milling requires advanced machines that can guarantee a high degree of consistency to close tolerances. The final plastic should not have any burrs.

Features of a good milling machine

You can assess the quality of polycarbonate milling process based on the following key parameters:

1. Positional accuracy that may range between 0.0002″ and over 12″.

2. Readability to +/- 0.00008″, especially for large scale milling processes.

3. Tolerances to +/- 0.0002″.

4. Both micro and deep hole drilling.

To achieve these, the milling technician should observe a well-defined procedure and machine parameters. The use of CNC machines has also eliminated obvious errors that were eminent. The technician should outline all operational conditions such as milling speed and efficiency of the milling tool.

CNC milling machine

At any given time, the approach will depend on the nature of the polycarbonate milling process at hand. For instance;

1. When end milling polycarbonate sheet, it is only sufficient fixturing that will allow for fast table travel, especially for high spindle speeds.

2. In face milling polycarbonate sheets, high shear geometry or high positive geometry cutter bodies can be used.

Differences between milling polycarbonates and metals

Polycarbonates and metals are different materials. For this reason, it is prudent that you note the following:

1. Thermal expansion is 10 times greater in polycarbonates than metals.

2. Since polycarbonates lose heat slowly than metals, you should avoid localized overheating during the milling process.

3. Polycarbonates are more elastic than metals.

Understanding these basic parameters will enable polycarbonate milling technicians to define their operational conditions aiming to get the best fabricated parts.

Polycarbonate milling fabricated products

Considerations in polycarbonate milling

Milling is a systematic process where the technician is required to follow certain rules to achieve the desired results. These include basic procedures before, during and after the milling process. These vital steps include:

Inspecting milling machine

Ensure all parts of your milling machine are in good working condition. That is, controller box, tool bit, spindle shaft, axis motors, spindle motor, vertical column, cross side and safety shield.

In the case of CNC machines, the software should be up to date and it should be simulated and tested to ensure the milling machine executes the right commands.

Coolant

Milling polycarbonates will obviously generate heat. This is common when you want to drill deep hole in polycarbonate sheet.

Choose recommended coolants that are inert. That is, they do not react with polycarbonate sheet. It should be compatible with the part. Do you remember the chemical properties of polycarbonates discussed in chapter one? Well, you should use it as your guide while choosing the best coolant.

Polycarbonate chips

Remove the polycarbonate chips consistently by blowing air or coolant. This is to avoid instances of these chips may leave scratches on machined parts.

Review machine operational parameters

These should include parameters such as right cutting speed and cutting tool feed rate. The two determine the nature of the finished part. Ensure there is no chatter. It will not only affect the accuracy of the finished part, but also reduce the life span of the cutting tool.

Basically, by observing these, you should be able to mill polycarbonate sheets successfully. Earlier, I had mentioned that this fabrication technique also go hand in hand with CNC rooting and vapor polishing polycarbonate sheets. What does the two techniques involve?

CNC Routing

This is an accurate polycarbonate fabrication technique that is considered to be more accurate. It produces smooth finishes on both curved and irregular surfaces. Here, the final products will also depend on the operational parameters of the routers. That is:

- A speed of 20,000 to 25,000 rpm.

- Router bits should be high-speed steel or carbide tipped.

- Bits with a diameter of 1/4˝ to 1/2˝ is highly recommended.

- Motor rating is also important – at least 1 horsepower.

- Observe feeding procedure – feed polycarbonate sheet against the rotation of the router.

The tolerance for errors can be controlled within 0.05mm. They are ideal when it comes to cutting, trimming and shaping polycarbonate sheets for any application.

Polycarbonate CNC routing product

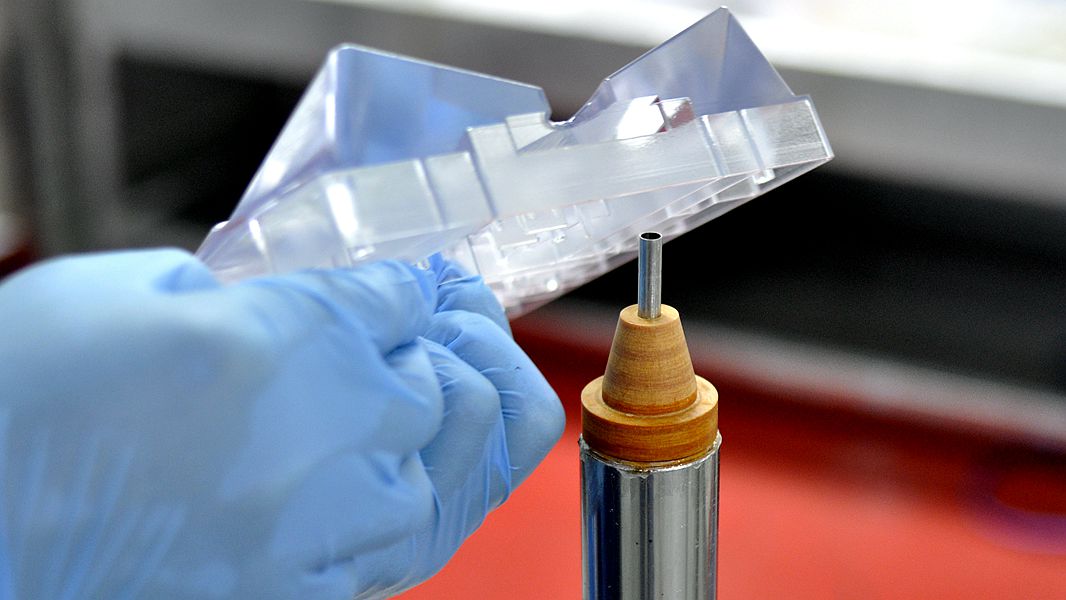

Polycarbonate Sheet Vapor Polishing

Polycarbonate fabrication companies use solvent vapor to produce polished surfaces. That is, the final surface will have an optically clear surface.

Basically, these companies apply chemicals that change plastic finish to have a high gloss. It is a delicate and technical process that requires people who understand the procedure.

Benefits of vapor polishing

This process has the following key benefits:

- Improved opaque and matte finish

- A glossy look

- Suitable for applications where no obstruction of light is required.

- Improves manifold application of polycarbonate sheets.

To achieve all these, you need to work closely with the polycarbonate fabrication technicians. Of course, all these finishing operations will depend on the specification stated on the CAD drawing. More importantly, you need to hire a company with qualified personnel and technicians to handle the process.

Apart from polycarbonate milling, thermoforming is also a common procedure used to shape these sheets into a desired shape. It is popular, just like milling and other fabrication methods discussed above.

Chapter Six: Polycarbonate Thermoforming

Polycarbonate thermoforming is a popular fabrication technique used in very many industries. Through this, companies can manufacture a wide range of equipment such as dome skylights, helmets, window shields, machine covers, etc.

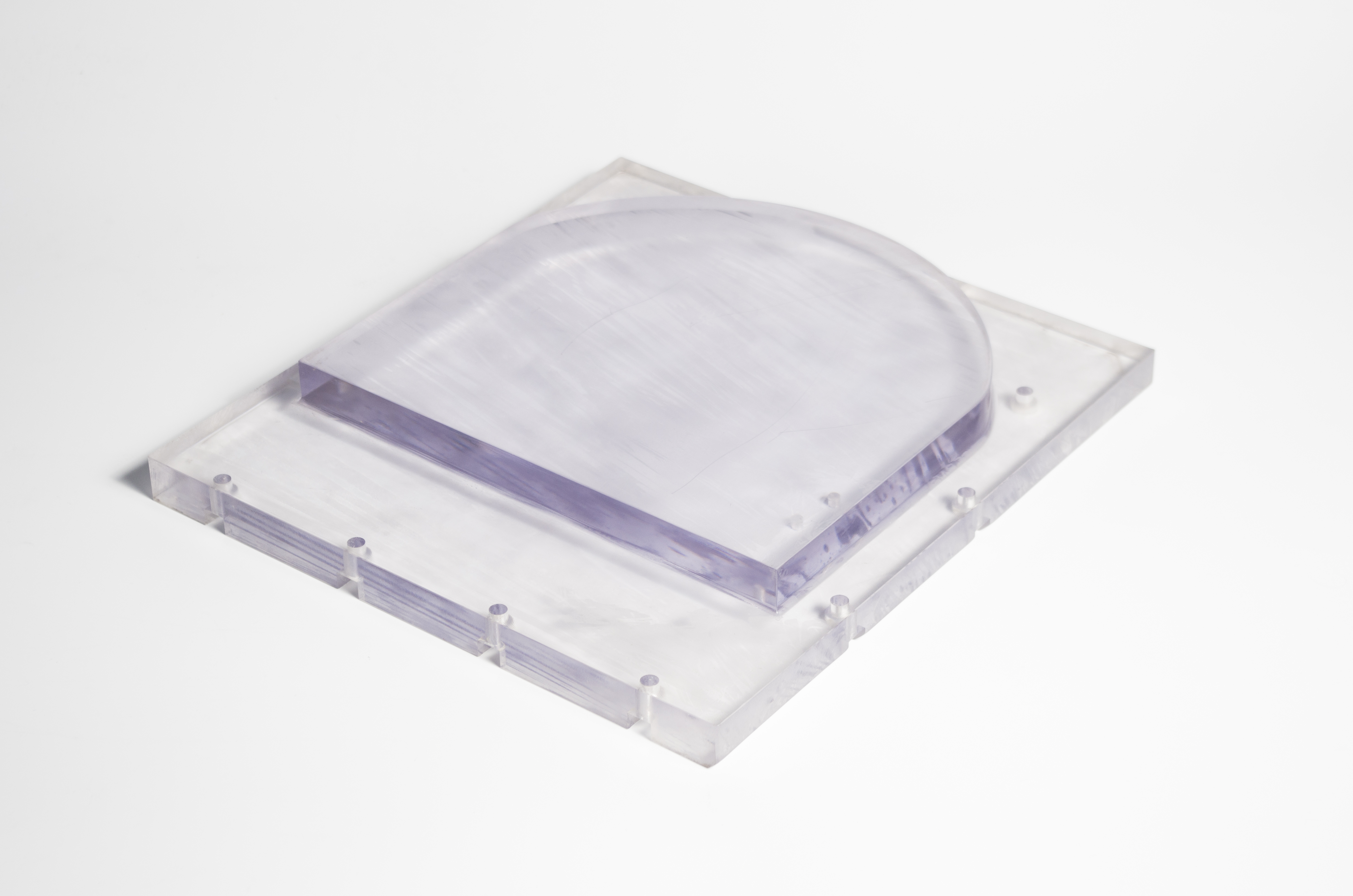

Thermoformed polycarbonate dome skylight

But, it is also one of the most challenging processes considering that the manufacturer must take a lot of precaution to fabricate the best equipment. Take for instance, polycarbonate tends to absorb water (about 3%), which can cause bubbles. Obviously, this will automatically undermine its effectiveness.

In this section, I will explore vital aspects of polycarbonate thermoforming. That is, it will help you understand how the entire process takes place and the key factors you need to consider.

Forming polycarbonates require the use of substantial amount of heat. The sheet must be heated uniformly. The amount of heat and duration which the heating process is done depends on a number of factors such as:

1. Thickness of the sheet.

2. Type of mold.

3. Degree of stretching required.

Still, as a general rule, the thermoforming process should be done at a temperature above 150°C. This is basically the glass transition temperature of polycarbonate sheet.

Processes involved in thermoforming polycarbonate sheet

As earlier stated, polycarbonate thermoforming is a systematic process that requires every technician to follow a well-defined procedure to achieve desirable results. This ranges from the sheet preparation to obtaining the actual product.

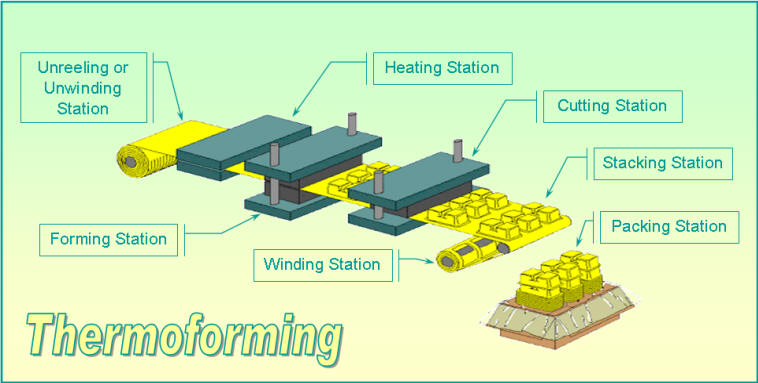

Polycarbonate thermoforming process

To go about this process successfully, you need to observe the following key steps:

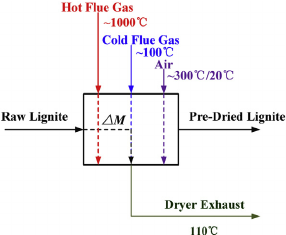

Pre-drying

Polycarbonate should be pre-dried at a temperature of about 125°C. The pre-drying time will depend on:

1. Thickness

2. Amount of humidity

May be, this may seem ambiguous, especially if you cannot determine the amount of humidity. Alternatively, you can go about this process by following these 4 essential steps:

- Take a sample of polycarbonate sheet and pre-dry to a temperature of 125°C.

- After about 2 to 3 hours, take the sample and heat it to a forming temperature that ranges between 170°C and 180°C.

- Inspect whether bubbles appear on the surface after about 10 minutes.

- No bubbles imply the polycarbonate sheet is dry. If bubbles appear, then it implies the sheet is not dry. You must repeat the process again.

NOTE: Ensure the sheet is completely dry.

Pre-drying process

Heating

Heat the polycarbonate to a temperature of 170°C and 180°C. Heat the sheet uniformly. Depending on the type of your machine, IR heating oven is commonly used. Of course, there are other types of heaters also available in the market.

Again, the orientation of the polycarbonate sheet will also depend on the type of machine used. In case you need to suspend the sheet, suspend it along the longer dimension.

The condition should be such that the heating process can be controlled. But, controlling the heating process will not prevent polycarbonate from shrinking.

Shrinkage is a common phenomenon that occurs when polycarbonate sheet is heated. It normally occurs in the direction of extrusion. This also varies depending on heating time and the thickness of the sheet.

Apart from this simple procedure, in industrial setup, the polycarbonate fabrication companies use radiation absorption graphs. Ideally, they play a crucial role when determining emissivity of a heating element. From this information, manufacturers can easily choose an efficient heating equipment.

Apart from the thickness of polycarbonate sheet, the complexity of the shape also determines the degree of heating required. That is, complex shapes may require more heat. Polycarbonate sheet begins to sag when it reaches a forming temperature.

NOTE: During the polycarbonate sheet heating process, it is important to take note of the following key factors:

1. For thin polycarbonate sheets, heat only one side of the sheet otherwise, opt for dual heating mechanisms.

2. Be careful when handling finished parts, polycarbonate parts tend to be very hot.

3. Try to control dirt and dust as possible. Polycarbonate sheets possess some static charge during thermoforming process.

4. In case there are hot spots during the process, reduce heating rate, allow heat to reach the center of the sheet uniformly or slow heating.

Thermoforming

After the polycarbonate sheet reaches the pliable temperature, it can be formed into a desirable shape depending on the type of mold.

The formed part should be allowed to cool. That is, it should be lifted off the mold when temperature has reduced to around 90°C. Again, there are higher chances of warping that will alter the thermoformed shape.

Polycarbonate thermoforming products

Moldings should be placed in counter bowed or cooling jigs. They should maintain the same position until a room temperature is achieved.

Thermoforming molds

This is an integral part of this process. Normally, the type of mold is dictated by the nature of the production process. For instance, when thermoforming polycarbonate sheets mainly for long production runs, cast aluminum molds may be a perfect choice.

Before the thermoforming process begins, the mold should be cleaned. This to avoid instances of dust marks on the final product.

Designing mold is a critical process where both the technicians and customers must participate actively to ensure they get the right design. It is from these that they can produce a wide range of their unique polycarbonate parts.

Polycarbonate thermoforming mold design is a challenging process. For instance, it is important to consider degree of shrinkage of polycarbonate sheet. As a technician, you need to analyze the heating and cooling cycle.

Polycarbonate thermoforming mold

Let’s consider some crucial aspects of a mold design.

Material used in making thermoforming molds

Like any other manufacturing process mold material plays a significant role here. You need to choose that material that will fulfill all polycarbonate fabrication process. There are two crucial factors anyone in this industry should consider:

1.Material

2.Heat transfer rate factor

The table below shows 6 main types of materials and their corresponding heat transfer values:

Type of mold material Average heat transfer rate factor

| Type of mold material | Average heat transfer rate factor |

| Aluminum | 6190 |

| Aluminum filled epoxy | 24 – 47 |

| Epoxy | 6.24 |

| Plaster of parts | 8.29 |

| Steel | 1238 |

| Wood/maple | 4.48 |

Remember, the choice of a specific mold type and design is mainly determined by the part size, finish, shape and length of production run.

Again, in vacuum polycarbonate thermoforming, the mold is designed to take about 15 psi. This implies that there is little wear on the mold.

How to design a mold

Having reviewed material and basic factors that determine the ultimate mold design, it is important to consider basic hints any designer should consider. These include:

Draft angle

On the lower side, it should be about 5°-7°. Normally, this will determine how easy it will be to remove the thermoformed polycarbonate part from the mold.

Vacuum holes

Use sufficient holes that will allow for faster evacuation of air. In the case of female molds, there should be holes at all deep draw areas.

Fillets and radii

It is advisable to use “generous radii” if possible. This will allow for more uniform walls and rigidity.

Types of forming process

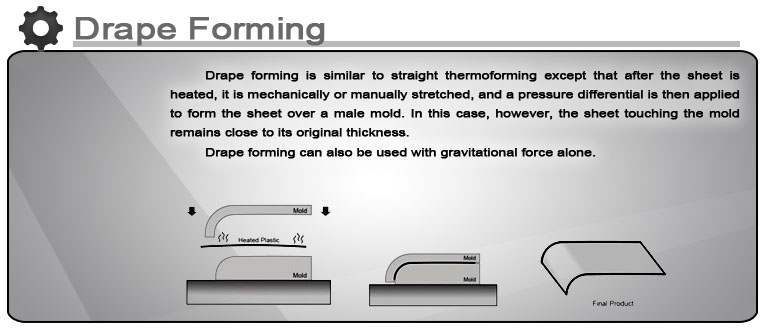

Generally, the two methods that are commonly used to fabricate polycarbonate sheets include drape and vacuum forming.

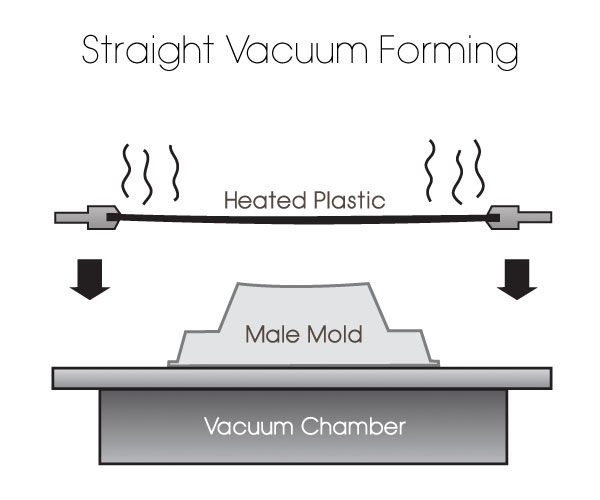

Vacuum forming

This is the simplified version of polycarbonate thermoforming. Normally, polycarbonate sheet is heated to a pliable temperature, stretched over a mold, then forced against the mold by a vacuum.

It is a versatile process where polycarbonate sheets can be formed to nearly any shape depending on customer requirements.

Vacuum thermoforming of polycarbonate sheet is popular in many industries due to its low-level technology, thus, cutting on unnecessary costs. Moreover, polycarbonate sheet is known for its high extensibility property, thus, suitable for vacuum forming process.

Vacuum forming process

In vacuum forming, polycarbonate sheet is pre-dried in shallow molds where the temperature should not exceed 160°C.

Choosing the right vacuum forming equipment is crucial here. In most cases, most polycarbonate fabrication companies opt for automated machines.

That is, those with IR heating with rotary and shuttle designs. Such equipment is characterized by the following key powerful features:

1. Time control that ensures accuracy.

2. Uniform heating.

3. Sufficient vacuum power.

These machines have two options – single heating and dual heating systems. The choice of a specific system will depend on the thickness of polycarbonate sheet. The dual heating systems are highly recommended where an affective heat penetration and even heating are required.

Vacuum forming tips

To go about this process successfully, you need to consider the following:

- Low-profile parts

- Use a straight vacuum forming in female molds. Remember, during this process, deep draw is not a requirement.

- For better material distribution

- Consider drape forming process (this will be discussed later in this chapter). It is essential for depth-to-diameter draw ratios.

- Snap-back

You can use it in the vacuum forming process, especially when reducing starting sheets. It also helps in material distribution and reduces chances of chill marks.

Billow plug

Highly recommended for the production of thin-wall items. Such items have a depth-to-diameter ratio of about 1.5:1.

Drape forming

This is yet, another popular manufacturing technique commonly used to make skateboards. It is a perfect choice in applications that require stronger, durable and flexible polycarbonate products.

Generally, drape polycarbonate thermoforming is suitable for uniaxial bent sections. Here, the molds used are mainly made from either wood or aluminum.

Drape forming

Here, polycarbonate sheet is heated to a temperature of 150°C, after which it is forced into a positive mold.

The polycarbonate sheet is forced into these mold while still hot and allowed to cool to room temperature.

Ideally, these are the main types of forming techniques in the polycarbonate fabrication industry. As a matter of fact, during the manufacturing processes, technicians have to deal with certain problems. These include:

Polycarbonate thermoforming problems & solutions

| Polycarbonate thermoforming problems | Possible causes | Suggested solutions |

| Mark off | Mold surface could be too smooth of mold surface too rough | Pre heat the mold or use extra fine emery cloth to lightly abrade mold surface. |

| Webbing | Sheet could be too hot or it could be due to improper mold spacing | Redesign the mold, reduce heating cycle and use mechanical assist/bridging |

| Bubbles and blisters | Polycarbonate sheet could be having too much moisture | Ensure the sheet is dry before beginning the thermoforming process. Use the tests highlighted above. Assess pre-dry oven temperature |

| Non-uniform sag | Uneven heating f polycarbonate sheet | Confirm whether heaters are in good condition. You need to screen “hot” areas. |

| Pinholes or surface marks | Vacuum holes may be too large | Reduce size of hole or get a smaller diameter vacuum holes. |

| Incomplete part formation detail | The are two possible factors: either there is inadequate vacuum or the sheet may be too cold | You should heat the sheet for longer period of time and ensure there is no leakage in the vacuum system. |

| Sheet pulls out if damping frame during forming | The polycarbonate sheet may be too cold to thermoform | The sheet requires further heating. Refer to the polycarbonate heating procedure discussed above. |

In short, thermoforming polycarbonate is a popular manufacturing technique commonly used in polycarbonate fabrication industry. However, the process may seem challenging if you fail to follow the recommended thermoforming procedure.

All thermoformed polycarbonate products may require additional finishing operations such as sanding or polishing. This is a common practice in polycarbonate fabrication industry. The two processed will be discussed in the chapter seven.

Chapter Seven: Polycarbonate Sanding and Polishing

At times, polycarbonate thermoforming may not produce the desired results. For this reason, the finished parts must go through another process – sanding/polishing.

PC vapor polishing

This is mainly for edge treatment where there should be both smooth and glossy. Remember, thermoformed polycarbonates tend to have sharp edges. This may hurt the end user of the product.

Normally, sand casting and polishing are considered to be the final finishing operations alongside other processes such as CNC routing, printing or bending.

Sanding and polishing are basically finishing operations. Finishing operations aim to remove any marks that the final component could have acquired during the molding or cutting process.

Polycarbonate sanding

Polycarbonate sheets can be sanded either by using dry or wet sanding techniques. Each of these techniques has a unique effect on the final appearance of the product:

1. Dry sanding may result in gumming

2. Wet sanding is known to produce a smooth surface finish.

In most cases, the sand parts may require further finishing operations to maintain the desired high gloss finish.

During any sanding operations, it is important to take note of the following:

Sanding polycarbonate lens

- Sanding process may result in excess heat build up. This may cause polycarbonate part to melt. In case you are using a machine sander, it is important that you monitor the possibility of heat buildup. That is, you need to reduce the sanding disc speed.

- Start as fine as you can achieve better results.

- Do not sand gouged plastics aggressively since this may weaken it.

- Start with a coarser grit before moving to the fine grit sandpaper.

- Sand flat and do not sand at a certain angle that may cause a dent on the surface.

With all these in mind, you should be able to get the best surface finish. Closely related to this is:

Polycarbonate polishing

There are quite a number of commercial sprays you can use to polish polycarbonate surfaces. Do you remember vapor polishing technique we had discussed earlier?

Well, it is one of the most popular method of polishing polycarbonate surfaces. It is mainly used in applications where the transparency of the polycarbonate products should be similar to that of the acrylic sheets.

It is advisable to use a 100% cotton cloth in any polishing process. These commercial sprays have glossy and a protective layer of anti-static agents. They contain specially designed waxes and solvents that do not react with polycarbonate sheets.

Polycarbonate sanding products

In short, you need to consider the two processes as you main polycarbonate finishing operations. Other finishing operations will be discussed in the chapter ten.

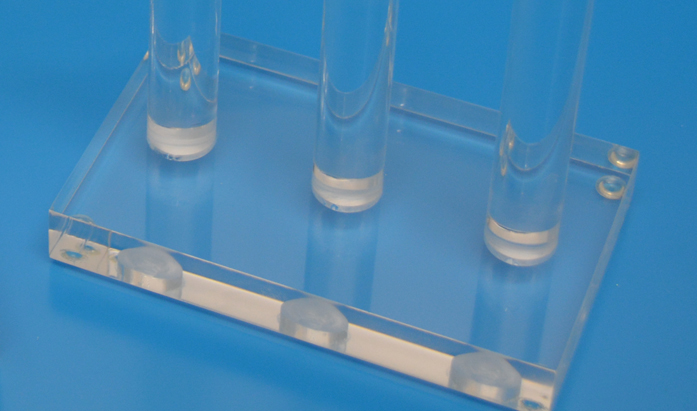

Chapter Eight: Polycarbonate Bonding

Assuming you need to make aquarium or a polycarbonate storage tank, the only option will be to bind polycarbonate sheets together. This implies, you must choose the right chemical compounds for this particular task.

As a matter of fact, polycarbonate bonding is quite different from acrylic bonding. This is mainly due to the intrinsic chemical and physical properties of polycarbonate sheet.

Polycarbonate bonding is an essential fabrication process. The best joint should be one that is smooth and clean. Again, the bonding material used must not react with polycarbonate sheet.

Polycarbonate bonding product

Unlike other material that require sophisticated processing techniques, polycarbonates are easy to bond either to itself or other material. All that matters is, technician should be able to choose the right adhesive for a specific task.

Types of polycarbonate bonding

Apparently, there is a wide range of technologies used to bind polycarbonate either to itself or other materials. The choice of a specific mechanism depends on scientific research as to whether a given technique is viable or not. Some of the most common processes include:

Polycarbonate solvent bonding

There are two main types of solvent bonding and these include:

1. Edge dipping

2. Needle type applicator that uses capillary action.

Polycarbonate solvent bonding

The main goal here is to ensure that the solvent bond is applied directly to the exact point where it should be. So, how can one go about the entire process?

The size of polycarbonate sheet to be bonded together play a significant role. In fact, it determines how you should apply these solvents. Let’s look at some of the most common options:

Joining smaller polycarbonate sheets

These surfaces can be bounded by placing the two pieces together and applying a bonding solvent along the joint. That is, where these two polycarbonate sheets meet. The solvent should flow along the entire joint.

Bonding polycarbonate

Joining thick polycarbonate sheets

You can immerse the two surfaces to be joined in the bonding solvent. Then join the two sections together.

NOTE: In both cases, you should clamp the two sheets in position until such a time that the bond will be set.

Again, the edges to be joined must be clean, smooth and apply even pressure in all sections.

It is worth noting that most solvents used in the polycarbonate bonding process may be associated with whitening.

Below are some basic procedure that can help reduce this phenomenon:

- Bonding process should be done in a controlled environment. That is, there should be low relative humidity.

- You can add about 10% glacial acetic acid. It reduces whitening at the joint.

- Use polycarbonate resin to thicken the solvent. This results in lower curing time, hence, reducing whitening.

- This is not the only bonding technique that can be used, another process is:

Transfer tape bonding

Transfer tape is commonly used for thin-gauge polycarbonate sheets. It is because it can produce a strong edge joint.

To apply transfer tapes, the surface should be cleaned may be with isopropyl alcohol water mixture. Apply the transfer tape, remove tape masking and press the two polycarbonate parts together.

Tape bonding

It is recommended that you roll all bonded surfaces with a rubber or wood. This aims to improve bond strength.

Welding

This is basically a mechanical way to bind polycarbonate sheets. It is basically an alternative method joining plastics thou it is not common due to a laborious procedure involved. Some of the most appropriate equipment for this task include:

Ultrasonic

Spin welding

Radio frequency

Polycarbonate fabrication companies can choose any of the three.

Since bonding solvents are the most commonly used techniques, it will be advisable is to explore some of chemicals constituents of these solvents.

Bonding solvents

They contain different chemical elements that have passed polycarbonate compatibility tests. These include:

Methylene chloride

It is one of the most popular compounds used in polycarbonate bonding. It is popular due to the following key reasons:

- Excellent bond strength

- Low capital investment

- Excellent optical clarity

Ideally, there are two options: ethylene dichloride and methylene chloride. The two can be mixed together, however, it is worth noting that this mixture has a slightly longer curing time. The good thing about this is that it gives technicians more time to put the parts in the right position.

Methylene chloride

As a general rule, you need to read the product data sheet before using this polycarbonate solvent bonding. Like I had stated earlier, you need to follow a defined procedure to ensure that your parts bond as required.

Some of these crucial steps include:

1. Test the solvent with a small part before you begin bonding critical sections.

2. The surface should be cleaned. For greasy stains, use Isopropanol (IPA).

3. You may dissolve about 2% to 5% of polycarbonate saw dust (just a recommendation). In case you opt for this, ensure the saw dust dissolves fully in the bonding solvent.

4. Add 10% of Glacial Acetic Acid to prevent whitening of the joint. In most cases, whitening does not occur. You can only try this in case whitening does occur.

5. Apply the solvent on one part, join them and apply uniform pressure for about five minutes

In any polycarbonate bonding process, you may consider either solvents or adhesives.

These are the most popular processes. Alternatively, you can try welding techniques, though, they have varying degrees of success. May be, this is the main reason why the method is not commonly used.

Other polycarbonate fabrication companies have also adopted lamination process. That is, they use an interlayer material (polyurethane). The application is common in manufacturing ballistic laminates where polycarbonate sheet is bonded to the glass.

Polycarbonate aquarium

Apart from these, there are other mechanical techniques such as screws or rivets. They are commonly used when to bond polycarbonate sheets with other materials such as wood.

In summary, you should only opt for that polycarbonate bonding technique you are well conversant with. Moreover, if you must opt for any solvent, then it must be one approved by a polycarbonate sheet manufacturer.

So, far, you must have learnt quite a number of polycarbonate fabrication processes. However, there is one that still remains – laser cutting.

Chapter Nine: Polycarbonate Laser Cutting

Like other materials, polycarbonate can be cut using laser machines. Normally, small gauges (about 1.5 mm thick) do not show any discoloration. However, thicker gauges are associated with light brown to dark brown burnt edges.

These conditions mainly depend on the installation and operational conditions. Therefore, you need to conduct preliminary polycarbonate laser cutting tests before starting on the main project. Of course, during this process, you will be able to optimize certain conditions such as:

Optimizing laser power to reduce whitening. This is a major phenomenon during laser cutting, especially if laser power and speed is not controlled.

Controlling unpleasant fumes that may come off during the process. You will be able to install appropriate ventilation systems.

Never induce stress on freshly laser cut parts. There is likelihood that it may break

About polycarbonate laser cutting

Cutting polycarbonate is a challenging process due to the additional processes that may be involved, especially when it comes to minimizing discoloration. As I had stated earlier, discoloration is a major problem when laser cutting thick polycarbonate sheets.

Polycarbonate laser cutting parts

Laser cutting is a technology that is popular in the modern manufacturing industry. However, it is an area that manufacturers are still investing resources to unveil the truth about certain unknown variables they encounter during the process.

Mostly, the CO2 laser machines are commonly used for this application. This is because the amount of energy it produces does not affect polycarbonate sheets.

In fact, it is the most common type of laser machine used to fabricate plastics. That is, they can be cut, engraved or marked using laser cutting machines. This is due to high flexibility and short set up time, just to mention a few advantages.

Polycarbonate laser cutting machine

Ideally, these machines cut polycarbonate sheets using a focused beam directed to the target using a pair of lens. That is, the infrared radiation removes all unwanted sections by burning and melting. This makes laser a perfect alternative in situations where other practices such as polycarbonate milling or cutting cannot produce a desired shape.

Ideally, this polycarbonate fabrication technique has so many benefits such as:

- Highly accurate, especially when cutting printing surfaces.

- No contact between laser light and polycarbonate sheet. Thus, no mechanical stress on the sheet therefore, problems such as scratched surface is completely eliminated.

- Smaller sizes can be cut economically.

- Faster way to fabricate polycarbonate sheet.

- Saves time during the preparation of the sheet since clamping is not a necessity.

To achieve all these benefits, you need to hire a company with a vast experience in laser fabrication. They should be able to produce intricate shapes or suggest other alternatives incase laser cutting cannot produce a desired finish.

Polycarbonate laser cutting parts

Precautions during polycarbonate laser cutting

When cutting polycarbonates using laser machines, it is important to follow these simple instructions:

1. Ensure laser machine is in good working condition and your workspace is well ventilated. This process is associated with some fumes. That is, you can use a vacuum table that will allow for more air to flow.

2. Direct most of the air on the polycarbonate sheet being cut to ensure that it cools during the process. Excess heat may lead to additional finishing operations that will increase fabrication costs.

3. Polycarbonate sheet should be suspended above the vacuum table. This is to eliminate any instances of any light that may bounce back from on the polycarbonate to burn spurs. It may leave marks on the laser cut sections.

4. You can use about 85% of power. Start with 10mm/sec as you adjust it slowly. The speed will depend on the thickness of the polycarbonate sheet.

5. Always strive to make the cut in one pass.

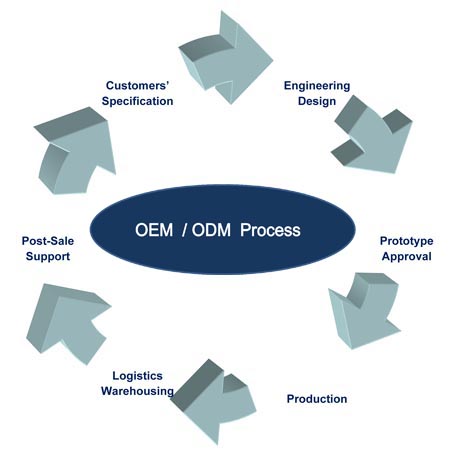

In short, polycarbonate laser cutting is an innovative solution in the plastic fabrication industry. Again, laser machines are somehow expensive, so, hiring an established company to go about the entire process for you (ODM and OEM clients) will be economical.

OEM and ODM process

Basically, these are the main polycarbonate fabrication methods commonly used in the manufacturing industry. However, these procedures may not be 100% perfect. Therefore, the processed parts may require other secondary operations. You can read this in the next chapter.

Chapter Ten: Polycarbonate Finishing Operations

Finishing operations, which is at times referred to as secondary operations are the last fabrication processes. Earlier in this eBook, we had discussed some finishing procedures such as vapor polishing, screen printing and sanding.

The nature of any finishing process will depend on the specific requirements of the reseller or product distributors. Of course, they will only tell the company what a consumer desire.

Furthermore, a finishing operation may be carried out specifically to customize a specific product for a company. That is, it may be used for branding purposes. A good example is hot stamping.

In this section, we shall explore more of these essential polycarbonate fabrication processes.

Types of polycarbonate finishing

Apart from those I had discussed earlier, other polycarbonate finishing processes include the following:

Hot stamping

It is a popular way of decorating finished polycarbonate sheets. This is a simple process that requires the polycarbonate fabrication company to: choose a good design, set required temperature and exert a significant amount of pressure on the sheet.

One of the most difficult process is creating a customized die in the hot stamping process. This could be a company’s logo or any branding sign. A good company should be able to design such stamps from any CAD drawings.

Hot stamping polycarbonate case

Normally, this process is conducted at a temperature of about 375°F. It is faster since it takes about 2 to 3 seconds to get a design stamped on a polycarbonate sheet.

Joint-planing

At times, the bonded polycarbonate sections may not have the desired shape or design. This is mainly due to misalignments of various polycarbonate sheets.

This makes a standard wood jointer planer a perfect choice for this task. However, you need to be keen not to cut too much into the surface. Again, choosing the right machine here is also an important procedure, especially when it comes to the cutting blade. Normally, you should opt for either high-speed steel or carbide.

As a general rule, you should only remove a small amount of stock on each pass. This could be 1/64 inches or even less. Normally, when you remove too much stock, there is a likelihood that the section may be rough. This may require additional finishing process, hence expensive.

Painting polycarbonate sheets

In case you are not a proponent of polycarbonate screen printing (already discussed), then you can opt for painting. There are so many options available in the market and you can easily customize a polycarbonate sheet to meet your specific requirements.

Painting polycarbonate sheet

Before the painting process begins, the surface should be clean and free from dust or residual paints. In most cases, you can mix water and Isopropyl alcohol in the ratio of 1:1. Use a soft cloth to clean the surface and ensure the surface is completely dry before you begin the painting process.

There are three conventional ways of applying this paint and these include:

- Conventional spray

- Brush

- Spray masked

Again, choosing the right paint is a crucial process at this stage. You need to know all the basic chemical constituents of the paint you are about to use.

Avoid paints with elements that may affect a polycarbonate sheet. These may include those that contain toluene, xylene or any other solvents mentioned in Chapter one. As a general rule, opt for those that are approved by the polycarbonate manufacturer.

There are a number of things that you must have in mind during this process. They include:

Side of the polycarbonate sheet to paint.

It is recommended that you don’t paint the surface with a polycarbonate coating e.g. scratch resistant coating.

Scratch resistant coating

Removing over spray

In most cases, you will use solvents to remove either over spray or drips. This solvent must not craze or attack polycarbonate sheet. Again, do not use objects that may scratch the surface of the sheet.

That is, avoid using objects such as knives, blades or scrappers. As a matter of fact, polycarbonate is not inherently scratch resistant. It is for this reason that it has to be coated with anti-scratch ingredients.

In summary, you can opt for any finishing operation depending on your specific needs and requirements. All that matters is the use of conventional means that will not damage the sheet.

So far, you have so many polycarbonate finishing options to choose from. These include:

1. Vapor polishing

2. Sanding

3. Joint-planing

4. Solvent polishing

5. Screen printing

6. Painting

7. Hot stamping

As you can see, you have so many options to choose from. Only go for one that suits your performance requirements.

Conclusion

Generally, this eBook explores all possible procedures that can be carried out during any polycarbonate fabrication process. Be it polycarbonate laser cutting, milling, bonding, finishing, bending or sheet printing.

It is important that one follows the recommended polycarbonate fabrication process. That is one that will not damage the sheet. This can only be possible if you hire the right company for this task.