Face shields are essential tools for safeguarding workers against workplace hazards like flying objects and chemical splashes. However, selecting the right face shield can be daunting due to the variety of materials, designs, and functionalities available. Consequently, Choosing a reliable and professional face shields supplier is crucial for ensuring product quality. Here are 9 factors to keep in mind when selecting a supplier for clear face shields.

1. What is the best Material for clear visor lens?

For sure, The material of the visor lens plays a vital role in the effectiveness and durability of the shield. Options include polycarbonate, acetate, PETG, steel, or nylon mesh. Moreover, each visor material offers specific benefits such as impact resistance, chemical splash protection, and clarity. Polycarbonate stands out for its exceptional impact and heat resistance, making it an excellent choice for versatile protection.

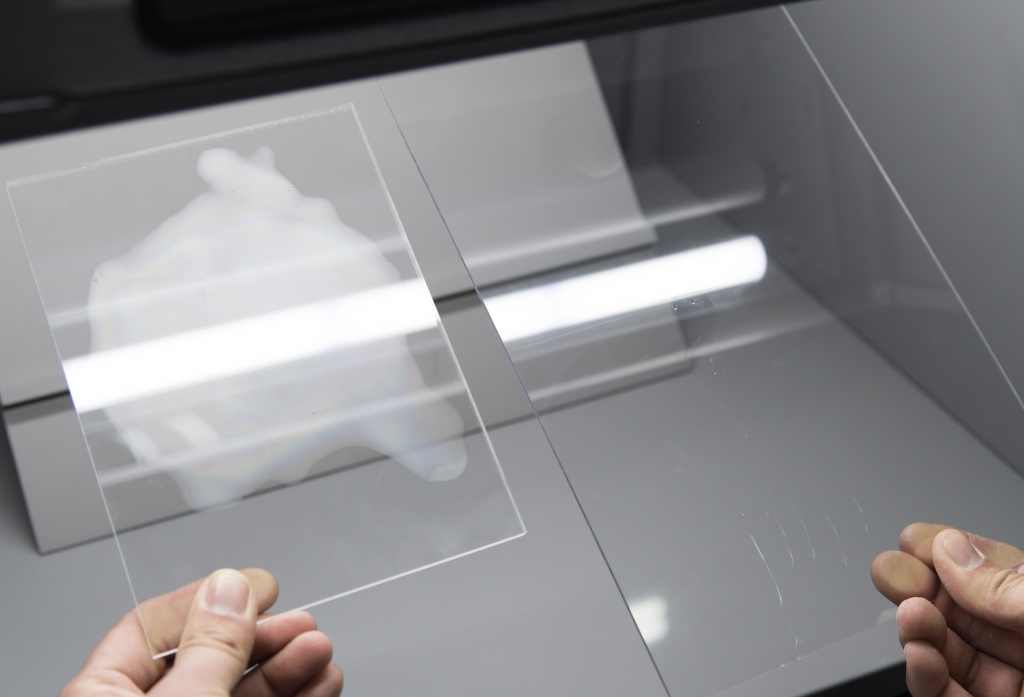

Polycarbonate face shields serve as transparent barriers between you and those you work with or serve. These clear shields typically consist of straightforward, rounded plastic sheets attached to protective glasses or a headband, allowing them to sit just in front of your face. Understanding the material is essential when seeking a professional polycarbonate fabrication manufacturer.

2, what is the manufacturing processes for clear face shield?

Two common methods for manufacturing face shield visors are extrusion and injection molding. However, Most of our Safety face shields are cut from extruded polycarbonate sheets.

Extruded safety face shields typically offer better impact resistance compared to injection molded ones. This is because the polycarbonate used in extrusion has a higher molecular weight, resulting in enhanced strength. Injection molding, on the other hand, requires a lower molecular weight polycarbonate with better melt flowing properties. However, lower molecular weight polycarbonate may have reduced strength compared to high molecular weight polycarbonate.

Moreover, Injection molding costs significantly more, making it unsuitable for small quantity or customized face shield orders.

3, Special treatment for personal protective equipment (PPE) face shields.

To ensure the clarity of face visors, certain special treatments are essential. Ensure that your face shields manufacturer offers these coatings as part of their services, providing a convenient one-stop solution.

Preventing fogging is crucial for ensuring clear visibility with a full-face shield. Anti-fog coatings, created with advanced technology, stop moisture from collecting on the polycarbonate lenses. This ensures continuous clarity even in tough conditions. Choose anti-fog coatings that have been tested under industry standards for long-lasting fog-free performance.

Protecting the polycarbonate lens with anti-scratch coatings enhances durability and prolongs the safety face shield’s lifespan. These coatings provide resistance against abrasions, making the clear shield easier to clean and maintain for long-term use in demanding work environments.

Anti-glare coatings minimize reflections and dissipate heat, optimizing visibility and comfort for the wearer. By reducing glare, these coatings enhance clarity and minimize distractions, allowing workers to focus on their tasks with precision and confidence.

Prevents static buildup on the eye protection, reducing dust and debris attraction.

4, Face shields Product Variety

Seek out a plastic fabrication supplier that provides a wide variety of polycarbonate face shield options tailored to diverse industry requirements. This includes offering various materials such as PET, polycarbonate, and acrylic, as well as diverse designs and plastic machining capabilities.

5, Ultra-Violet Protection

Protecting against harmful UV radiation is vital for personal protective equipment (PPE) used in environments with intense UV sources. Specialized face shields are designed to block UV transmission across all wavelengths, offering comprehensive protection for workers exposed to UV radiation.

Ensure that your polycarbonate visor manufacturer understands this requirement, and that all your polycarbonate visors undergo UV treatment.

6, Customization Options

Choose a plastic machining supplier that offers customization options to tailor your face shields according to specific requirements, such as CNC machining, tinted face shields, thermoforming or special features.

7, Pricing

When seeking pricing information, ensure transparency in pricing structures. Additionally, Clarify whether the polycarbonate sheet requires a specific thickness, surface coating, or machining mold. Request clear breakdowns of costs, including any discounts for bulk orders, and details of additional charges for customization or shipping for new face visor orders. Contact us for more details.

Being located in China, Excelite benefits from being situated in the world’s factory. This enables us to leverage abundant resources, offering competitive prices without compromising on quality.

8, Customer Support and Service

Prioritize suppliers that offer excellent customer support, with responsive communication and efficient resolution of inquiries or concerns. This ensures a smooth purchasing experience for you.

Our teams in China and Australia are available 24/7 to provide you with instant quotes.

9, References and Reviews

Evaluate the reputation of the face shields supplier by seeking references from past customers or reviewing testimonials online. This will help gauge satisfaction levels and reliability. Additionally, consider the supplier’s project experience. For example, Excelite has successfully completed projects including ballistic face shields for army, air filtration solutions, sandblasting lenses, bike helmet visors, and millions of anti-fog lenses during the COVID-19 pandemic.

As a result, while selecting the right supplier for clear face shields is crucial for ensuring product quality and worker safety. When evaluating potential suppliers, consider factors such as the material of the visor lens, manufacturing processes, special treatments offered, product variety, UV protection, customization options, pricing transparency, customer support, and supplier reputation.

Excelite, located in China, stands out as a reliable option, leveraging its position in the world’s factory to offer competitive prices without compromising on quality. By prioritizing these factors and partnering with a reputable supplier like Excelite, businesses can secure high-quality face shields tailored to their specific needs, ultimately enhancing workplace safety and efficiency.